Innovation and reliability for machine tools

IGUS ITALIA

Pad. 13 stand C23

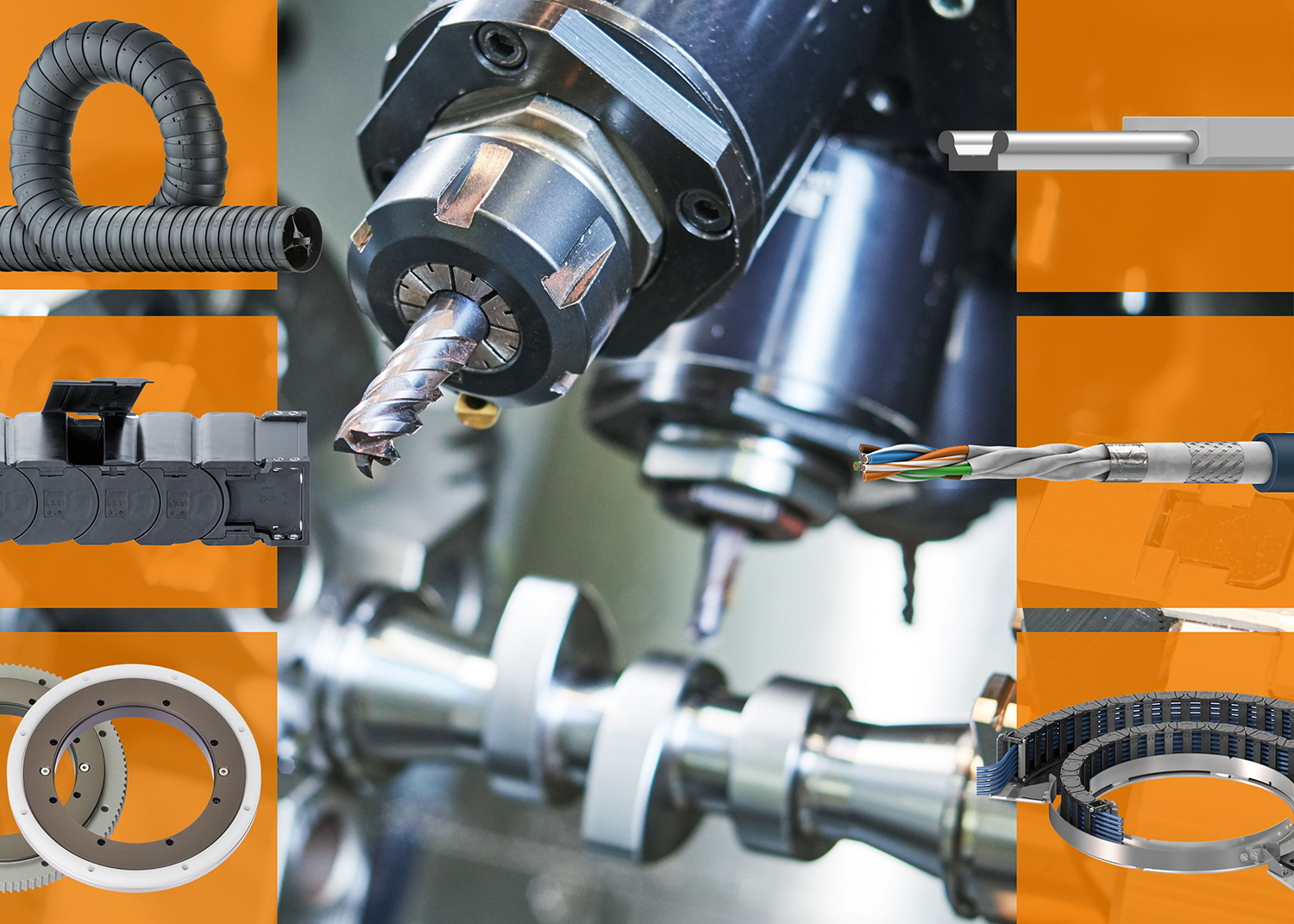

Igus confirms its participation in the 34th edition of BI-MU, the leading Italian event dedicated to the machine tool, robot, automation, digital and additive manufacturing, auxiliary and enabling technologies industry (Fieramilano Rho – 9/12 October 2024). Within the exhibition space (Hall 13 – Stand C23), the motion plastics specialist will present a wide range of innovative solutions designed specifically for the machine tool industry. Visitors will have the opportunity to discover the latest additions to the igus catalogue, all characterised by maximum reliability and quality excellence, together with the longest guarantee period on the market, recently extended to 4 years.

Igus confirms its participation in the 34th edition of BI-MU, the leading Italian event dedicated to the machine tool, robot, automation, digital and additive manufacturing, auxiliary and enabling technologies industry (Fieramilano Rho – 9/12 October 2024). Within the exhibition space (Hall 13 – Stand C23), the motion plastics specialist will present a wide range of innovative solutions designed specifically for the machine tool industry. Visitors will have the opportunity to discover the latest additions to the igus catalogue, all characterised by maximum reliability and quality excellence, together with the longest guarantee period on the market, recently extended to 4 years.

Best-selling solutions in the spotlight

At the igus stand, the spotlight will be on the igus best sellers, including the R2.1 closed cable carriers. Made of igumid material, those energy chains resist hot swarf and even incandescent swarf, effectively protecting cables during milling and turning operations. Available in inner heights of 26, 40, 48 and 75 mm, the R2.1 chains have lids that are openable from both sides along the inner or outer radius and are designed to provide a tight seal, with strong double stop-dogs for high fill weights and unsupported lengths.

Innovation for machine tool rotations

Also on show at BI-MU was the complete range of components developed by igus for rotations in machine tools, including cables for torsional applications, the RBR energy chain system, the HD twisterband and the unique triflex® multi-axis cable carrier. These innovative solutions effectively solve the main complexities involved in guiding hydraulic or pneumatic cables and hoses in turning and screwing operations. Also ideal for a wide range of rotational applications are the PRT polymer slewing ring bearings, available in various versions – with internal or external toothing, with or without angle stops – that allow smooth dry rotations, for example in turntables, even under high loads.

Linear systems

The igus range for the machine tool world also includes the linear systems of the drylin W series. Completely free of lubrication, these linear axes ensure excellent sliding properties and wear resistance, even at high speeds. Essential characteristics in this ultra-technological sector where plants often operate in 3 shifts, 7 days a week.

Smart plastics and LCA for the 5.0 transition

Also on show at BI-MU will be the wide range of igus solutions for the 5.0 transition, the new direction towards which the entire industry is moving. During the event, visitors will have the opportunity to discover how these technologies can help the machine tool industry. Smart plastics, equipped with intelligent sensors, allow continuous monitoring of individual components, and enable effective predictive maintenance planning. In addition, low-cost automation systems and advanced digital tools, such as the igusGO app, now also available in Italian, make it possible to optimise machine tool production processes, facilitating the work of engineers and designers.

![]()

![]() * The published news is edited by exhibiting companies. Exhibitor assumes responsibility for what is published in his own page.

* The published news is edited by exhibiting companies. Exhibitor assumes responsibility for what is published in his own page.