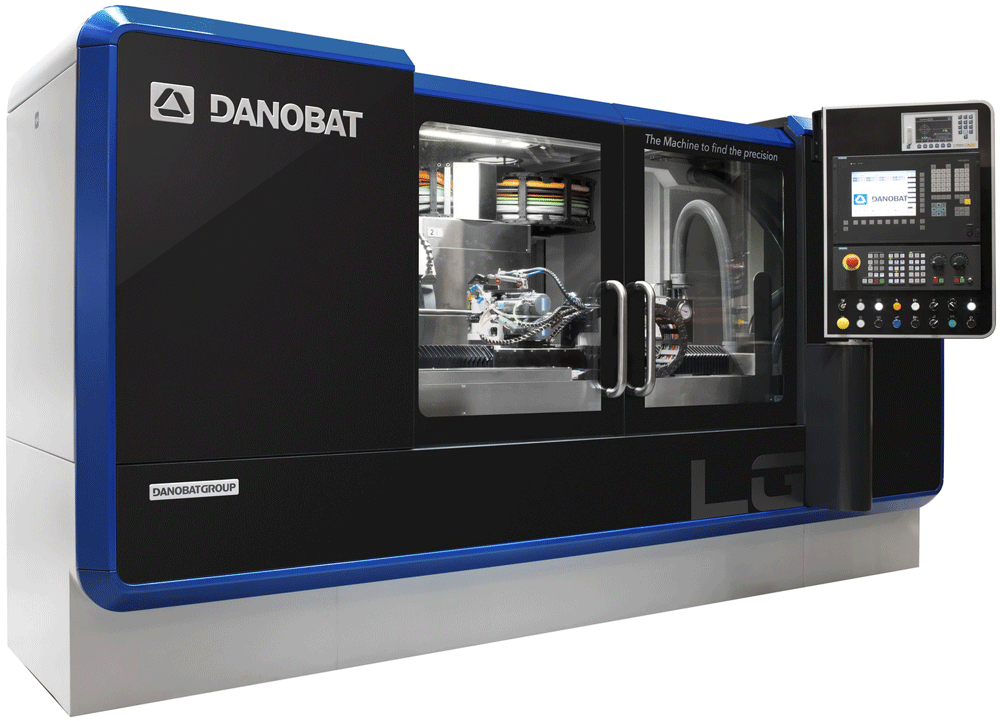

High performance external cylindrical grinding machine

DANOBAT

Pad. 11 stand E16

The range of LG external grinding machines is the solution that combines the highest levels of productivity, precision and quality with the right level of flexibility, thanks to the availability of different wheelhead configurations and a wide range of accessories and external or integrated automation systems.

Technological features of the LG include:

Excellent ergonomics, wide range of automation solutions.

Natural granite base, excellent thermal stability, rigidity and vibration damping.

Machine axes driven by linear motors, linear guides with preloaded rollers.

The wheel spindles can reach a peripheral speed of 120 m/sec, combined with the wide range of wheelhead configurations, which allows the use of different types of grinding wheels.

Wheelhead B-axis is driven by an integrated torque motor and controlled by a high-resolution absolute encoder, with pneumatic clamping and unclamping.

A wide range of accessories and options are available.

It is possible to connect the machine to any type of automation system, both external and integrated.

The SIEMENS CNC is combined with the new DoGrind+ user interface, which is completely developed by Danobat.

Availability of the Danobat Digital Suite software package for Industry 4.0.

TECHNICAL DATA (standard)

Max. distance between centers 400, 600 and 1.000 mm

Max. diameter to be ground 290 mm

Max. weight between centers 50 / 80 kg

Max. grinding wheel dimensions 500 x 100 x 203,2 mm

Max. wheel peripheral speed 63/80/120 m/s.

![]()

![]() * The published news is edited by exhibiting companies. Exhibitor assumes responsibility for what is published in his own page.

* The published news is edited by exhibiting companies. Exhibitor assumes responsibility for what is published in his own page.