piFLOW conveyors and MPS Ultrasonic Screening Stations

PIAB GROUP

Pad. 15 stand G37

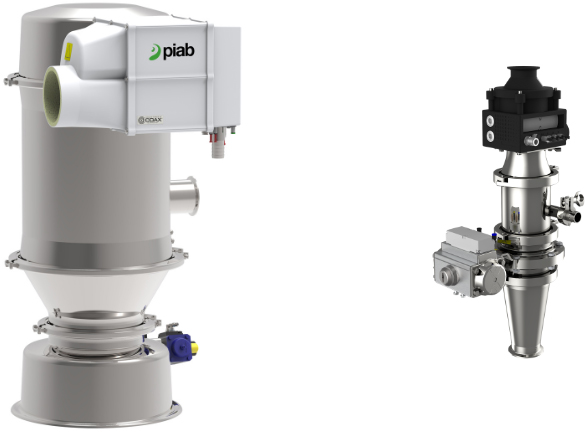

piFLOW® conveyors for automated handling of metal powders and metal alloys

These conveyors enable the transfer of materials with a bulk density of 8 kg/liter at a significant flow rate. They are based on the highly efficient and patented COAX® vacuum technology. The transport occurs in a closed cycle, which is gentle and preserves the purity of the product, preventing degradation. The conveyors are ATEX certified for dust and gas, and feature integrated automatic filter cleaning. No component weighs more than 15 kg, and no tools are required for cleaning and maintenance.

2 available conveyor types:

- piFLOW®p: Conveyor designed for transferring powders with high-quality requirements

- piFLOW®am: Compact conveyor designed to meet the needs of OEMs in the additive manufacturing sector.

Advantages:

- No exposure to metal dust for operators

- Eliminated risk of cross-contamination

- Full traceability of batches.

Applications:

- Feeding 3D printers

- Feeding vibrating screens and hoppers

- Recovering metal powders.

MPS Ultrasonic Screening Stations for Metal Powder Recovery

MPS Ultrasonic Screening Stations for Metal Powder Recovery

These stations allow for efficient processing and recovery of powder materials in various additive manufacturing processes. Three types of stations are available:

- MPS 5 with manual operation

- MPS 30 with semi-automatic operation

- MPS X1 with automatic operation.

Advantages:

- Compact footprint with a solid and durable design

- Easy to use and move if necessary

- Economically efficient due to high longevity, high-performance screening modules, and proven handling technology for reduced process times

- High quality of recovered material

- Safe process with no risks to operators

- Compatible with all common 3D printing systems.

![]()

![]() * The published news is edited by exhibiting companies. Exhibitor assumes responsibility for what is published in his own page.

* The published news is edited by exhibiting companies. Exhibitor assumes responsibility for what is published in his own page.