5-axis overhead gantry milling centre for hi-tech materials

JOBS

Pad. 11 stand D12

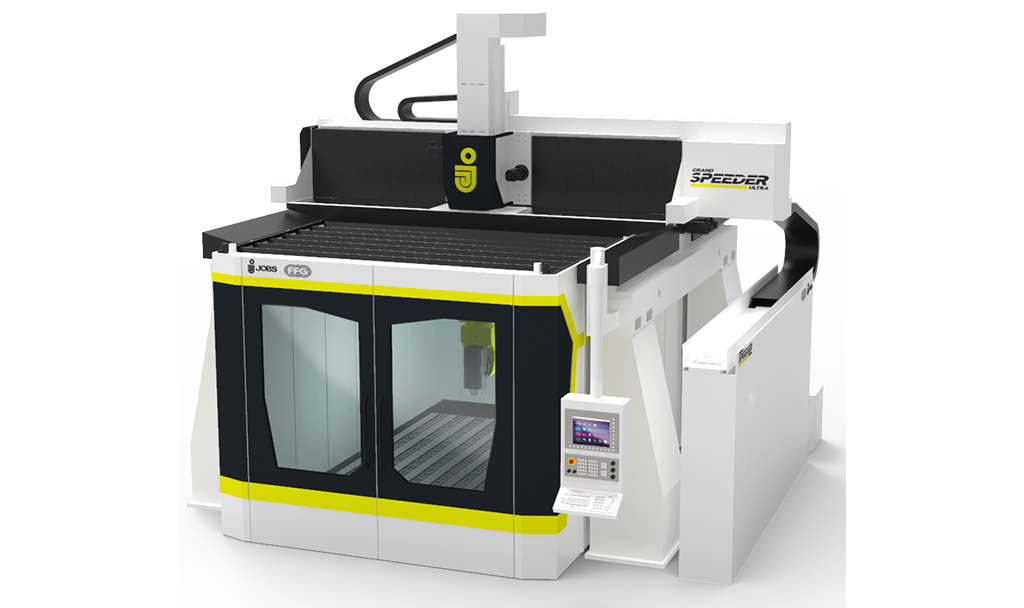

Jobs developed a new machine model belonging to the Speeder line, called GrandSpeeder Ultra. This line is the result of Jobs’ technological innovations aimed at reducing operating costs, simplifying maintenance and adopting environmentally conscious and energy-saving technical solutions.

The newborn model Jobs GrandSpeeder Ultra is a 5-axis overhead gantry milling centre with high dynamic performances, integrating design and functional solutions specifically aimed at cutting high-tech materials, especially at the machining of composite parts in aerospace applications or sports cars, at the creation of style models in the automotive field and at the finishing of aluminum dies.

The modularity of linear axes starts from X 3000 mm, Y 2700 mm, Z 1200 mm up to X 9000 mm, Y 4000 mm, Z 2500 mm. Axis dynamics are outstanding: X/Y 80 m/min and Z 60 m/min. This milling machine is equipped with proprietary UltraHead featuring backlash free kinematics for continuous 5-axis operations (C-axis | A-axis ±270° | ±130°) and high-speed direct-drive spindle 25(22) kW 32(28) Nm 20000 rpm HSK-A-63.

Jobs GrandSpeeder Ultra is fitted with an excellent enclosure ensuring efficient containment of machining wastes, high accessibility, ergonomics and safety for the operator and can be installed on an industrial floor without the need for specific foundations.

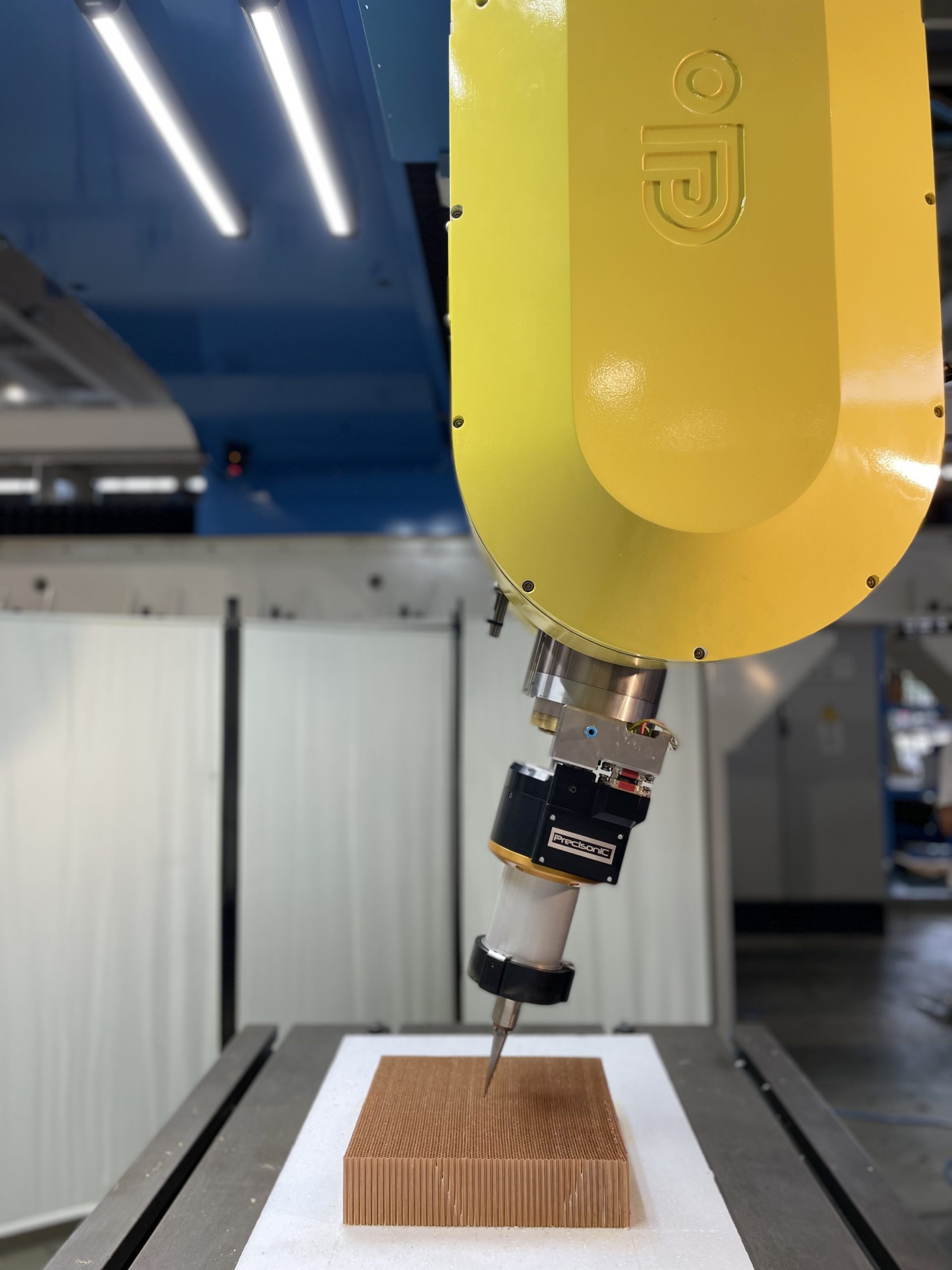

In addition to milling operations, GrandSpeeder Ultra allows the use of ultrasonic tools for cutting operations on honeycomb material.

In order to enhance its machining performances, the machine can also be equipped with several accessories such as: optical scales, wide choice of worktables, onboard 8-pos. tool magazine or chain-type tool magazine up to 40 pos., part probe and laser probe, tool lubrication with spray mist, suction hood, retractable roof, surveillance system, dual work-area, pallet changer.

![]()

![]() * The published news is edited by exhibiting companies. Exhibitor assumes responsibility for what is published in his own page.

* The published news is edited by exhibiting companies. Exhibitor assumes responsibility for what is published in his own page.