Roller Linear and Manta for 34.BI-MU

OMV

Pad. 15 stand D04

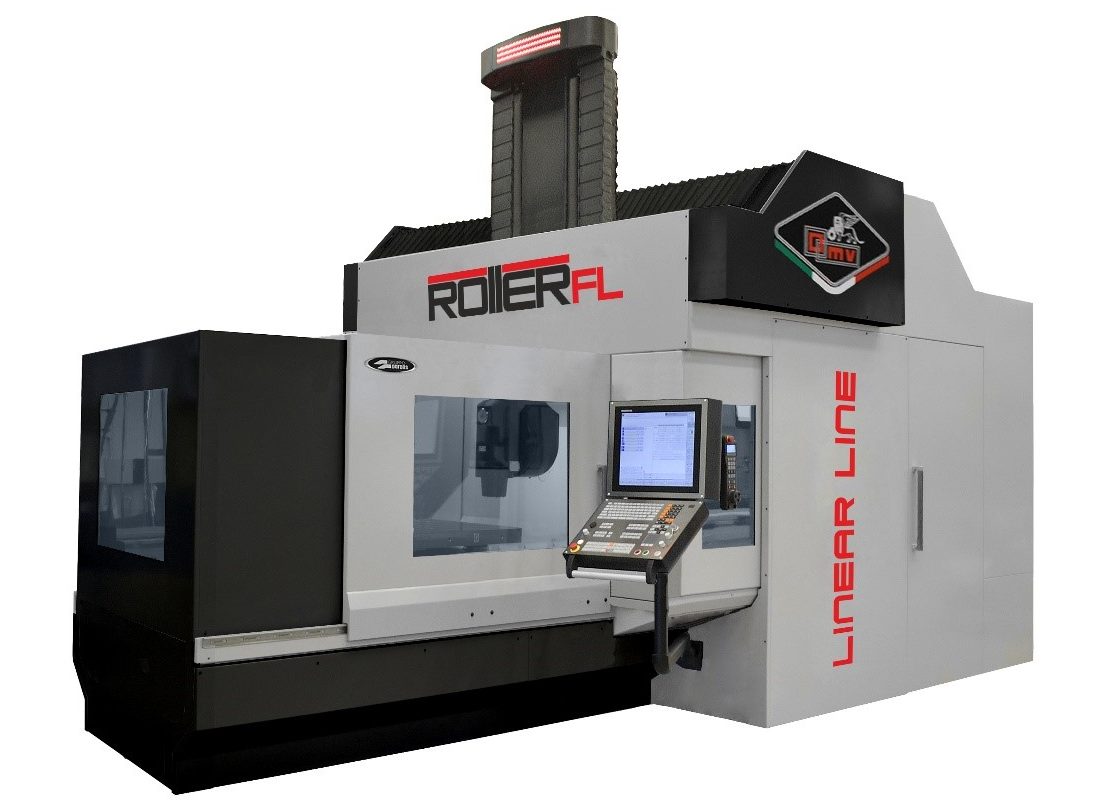

High speed bridge type milling center Roller full linear

Bridge type machining center with mobile table with 5 continuous working axes at very high speed with innovative solutions and cutting-edge performances. The structures, designed with the aid of powerful calculation and analysis software systems, are made of steel alloy to ensure maximum dynamism, to ensure rigidity and precision and subjected to a relaxing heat treatment to remore residual mechanical tensions.

Rapid feed speed 60.000 mm/min.

Travels: Longitudinal 2200 / 3000/4000 mm.

Cross 2030 mm.

Vertical 1000 mm.

Work table 2100/3100/4100 mm.

Advantages: transmission with linear motors and pressurized optical scales for very high precision and reliability.

Application : Molds for automotive, aerospace, packaging and very high precision mechanical processing.

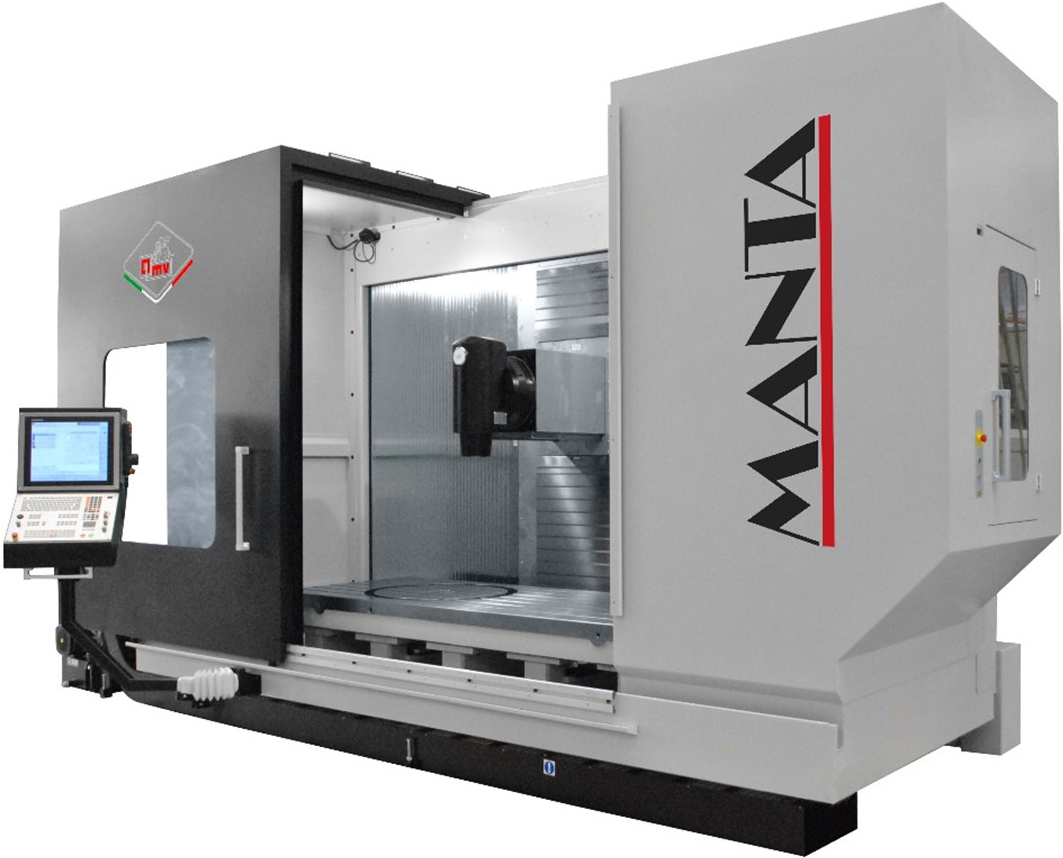

Manta is a high-speed milling centre

MANTA is a high-speed milling centre characterised by its fixed bed and moving column configuration. Designed with the aid of modern optimisation Softwares using Finite Element Methodology (FEM), it features an excellent combination of rigidity and vibration damping. With the addition of low friction guides and high axis accelerations, it has all the characteristics that enable it a particularly dynamic performance both in roughing and in finishing.

All this brings benefits to the economy of the entire machining cycle.

MANTA has been designed to meet the widest and most diversified customer requirements by satisfying 3,4 and 5-axis machining needs.

Travels: Longitudinal 2200 / 2600 mm.

Cross 900 mm.

Vertical 1000 mm.

Work table 2500×1000 / 2900×1000 mm

Rapid feed speed up to 40 m/min.

The linear axes, equipped with Brushless motors, have precision preloaded double ballscrews with a total backlash elimination.

The linear guides are high-precision components with preloaded recirculating roller bearings with a low centre of gravity.

Displacement control and axis positioning are achieved with Heidenhain direct optical transducers.

MANTA can be equipped with a 700 mm diameter rotary table with a load capacity of 1500 kg

and TORQUE motor. It is recessed in the work table and is also available in a turning version.

The head is equipped as standard with an OMV MTS motor spindle with 37 kW and 117 Nm or with 47 kW and 190 Nm (optional) with rpm ranging from 12000 to 22000.

It has an inclination range of +- 120 degrees and is driven by a TORQUE motor with resolution of a thousandth of a degree.

Options include a high-pressure coolant system inside the spindle (20 – 50 – 80 bar) and the passage of air outside and inside the spindle.

The column and saddle (box in the box configuration), basement and ram are made of electro-welded steel with special stress relief and stabilisation treatments.

The workpiece table is made of high-density cast iron.

The weight of the vertical movement unit is compensated by means of a hydraulic cylinder system.

The enclosure, which has large windows, is equipped with a door that slides outwards, thus providing full access to the work area to facilitate workpiece loading and unloading operations.

The electrical cabinet, with IP55 protection, is equipped with an air conditioner.

The hydraulic system consists of an independent control unit composed of a variable capacity electric pump with adjustment and control pressure switches.

The operator console is mounted on a multi-jointed arm for maximum ease of movement and is complete with remote electronic handwheel and 19″ video.

The drum tool changer magazine is located completely out of the machining area and has a minimum of 40 and a maximum of 60 pockets.

The swarf conveyor is positioned in front of the work table and it is easily removable for cleaning and maintenance.

Working center with fixed portal and mobile table Active Five full linear model

Work center fixed portal and mobile table with 5 axes in continuous working at very high speed with innovative solutions and cutting-edge performance. The structures, designed with the help of powerful software systems of calculation and analysis, are made of steel alloy to ensure maximum dynamism, widely dimensioned to ensure rigidity and precision and subjected to a thermal treatment to eliminate mechanical stress.

Fast feed: 60,000 mm/min.

Strokes: Longitudinal 2200 / 3000/4000 mm.

Transverse 2030 mm.

Vertical 1000 mm.

Worktop 2100/3100/4100 mm.

Advantages: transmission with linear motors and pressurized optical lines for very high precision and reliability.

Application areas: Molds for automotive, aerospace, packaging and high precision machining.

![]()

![]() * The published news is edited by exhibiting companies. Exhibitor assumes responsibility for what is published in his own page.

* The published news is edited by exhibiting companies. Exhibitor assumes responsibility for what is published in his own page.