The future of advanced manufacturing

INNSE BERARDI

Pad. 15 stand E24

Camozzi Machine Tools, represented by the two sister companies Innse-Berardi & Ingersoll Machine Tools, welcomes you to 34.BI-MU to experience the future of advanced manufacturing. Come and visit us to discover how Camozzi Machine Tools can be your tech partner for:

Camozzi Machine Tools, represented by the two sister companies Innse-Berardi & Ingersoll Machine Tools, welcomes you to 34.BI-MU to experience the future of advanced manufacturing. Come and visit us to discover how Camozzi Machine Tools can be your tech partner for:

• Subtractive Manufacturing: vertical, horizontal, and special machines.

• Additive Manufacturing: producing one of the largest 3D prints in the world.

• Fiber Placement: supplying the most important space players with our automatic fiber placement machines for space rocket construction.

We would like to introduce you to our range of products: from very large and sophisticated machines to compact and universal machining centers. The latter is well represented by the Atlas Vision G, a vertical movable gantry machining center suitable for multipurpose machining.

It offers several unique features, such as the ability to configure the machine with multiple processing areas that are completely independent and separable. Through the CNC panel with a tool monitoring system, the operator can manage the automatic attachment head changer, the tool magazine, and the tool management system, minimizing machine downtime and increasing productivity.

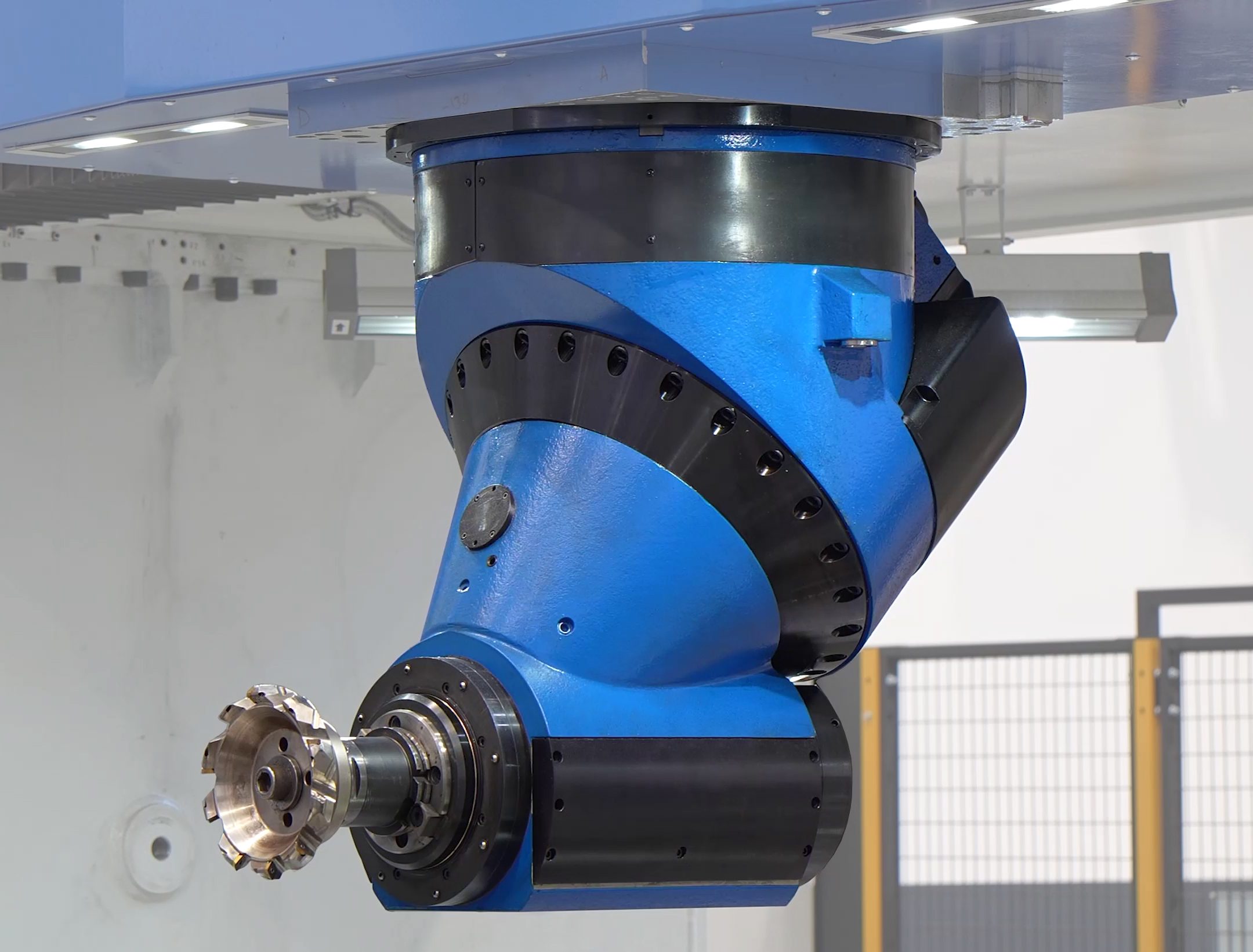

It is equipped with a universal TUA45 head (see picture) for 3+2 machining, featuring high-speed and high-accuracy rotating axes configuration. The head can assume 360.000 positions (every 0.001°) and has a refrigerated body for thermal stability.

The machine also features two large-section, high-capacity conveyors and one independent elevator for full workspace visibility. It is enclosed with perimeter safety fences for full protection.

So, if you are looking for a compact and universal machine to enhance your production capabilities, improve product quality, and strengthen commercial relationships with partners, this is the right choice. Atlas Vision G allows the machining of larger pieces and the execution of complex operations such as milling, drilling, and threading with the result of a reduction of production time and delivery schedules and stronger reliability.

And this is not all: Innse-Berardi machines are Industry 5.0 ready. Equipped with two software solutions: IBNET for centralized real-time plant control and IBRM for predictive detection and proactive assistance, you can easily perform remote maintenance and monitoring of your machine.

![]()

![]() * The published news is edited by exhibiting companies. Exhibitor assumes responsibility for what is published in his own page.

* The published news is edited by exhibiting companies. Exhibitor assumes responsibility for what is published in his own page.