Category: Senza categoria

Events

34.BI-MU: past events of presentation

There are many events where the secretariat of the fair participated with the aim of presenting 34.BI-MU, the new format of the 2024 edition and its exhibition themes.

![]()

Events where they talked about 34.BI-MU or where it was possible to meet the staff of the event:

27 June 2024

MACCHINE GEMELLE 2024. QUANDO IL VIRTUALE SUPERA IL REALE, Industrial Village, Torino (sixth approach event)

25 June 2024

ADDITIVE MANUFACTURING PER LA SOSTENIBILITÀ, Trentino Sviluppo, Rovereto, TN (fifth approach event)

14 June 2024

MANUTENZIONE PREDITTIVA: DRIVER PER LA SOSTENIBILITÀ, CIM 4.0 Competence Center Torino (fourth approach event)

18 April 2024

AIDAM MEETING, Step, Milano

11 April 2024

ROBOTICA E AUTOMAZIONE: SFIDE E OPPORTUNITÀ PER IL FUTURO DELLA PRODUZIONE, Km Rosso, Bergamo

10 April 2024

SMART MANUFACTURING SUMMIT, Milano City Life, Milano

28 March 2024

L’ADDITIVE NEL MOTORSPORT, Villa Griffone – Museo Guglielmo Marconi, Sasso Marconi, BO (third approach event)

22 February 2024

THE COMPOSITES, webinar online

13 December 2023

UCIMU: END-OF-YEAR PRESS CONFERENCE, Palazzo Giureconsulti, Milano

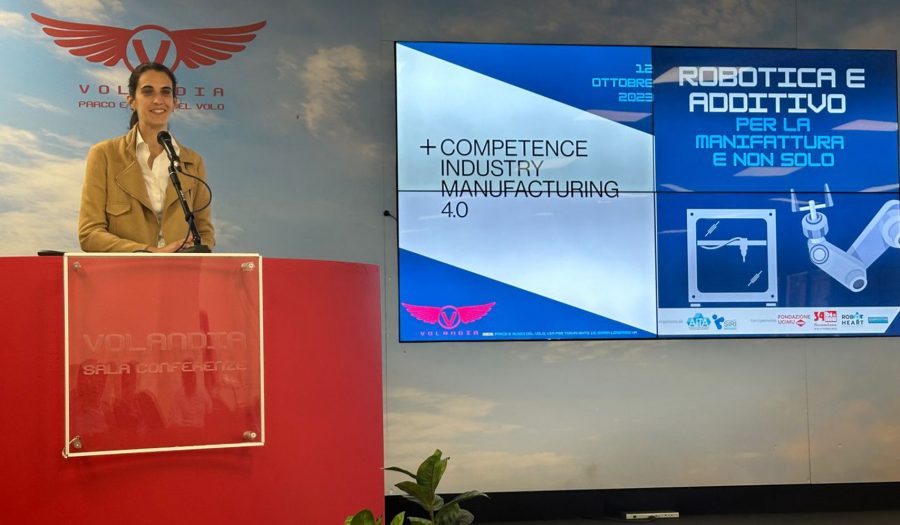

12 October 2023

ROBOTICA E ADDITIVO PER LA MANIFATTURA E NON SOLO, Volandia, Malpensa VA

19 September 2023

PRESS CONFERENCE PRESENTATION OF 34.BI-MU, EMO Hannover, Hannover DE (second approach event)

5 September 2023

INNOVATIVE INDUSTRIAL 3D PRINTING, Baker Huges, Firenze

11 July 2023

WOMEN IN 3D PRINTING, MADE Competence Center, PoliMi Campus Bovisa, Milano

22 June 2023

INTELLIGENZA ARTIFICIALE: IL FUTURO È QUI, webinar online

8 June 2023

LA CONVENTION DELLA MACCHINA UTENSILE E DELLA MACCANICA, Museo Alfa Romeo, Arese MI (first approach event)

28 April 2023

AIdAM General Meeting, Museo Alfa Romeo, Arese MI

20 April 2023

ADDITIVE MANUFACTURING Ripensare i processi industriali per la produzione del futuro, Km Rosso, Bergamo

4 April 2023

MACCHINE PROTETTE, Expo Fiera, Piacenza

![]()

![]()

34.BI-MU promotion stand at trade fairs:

IMTEX (Bangalore, 19-25 January 2023), TIMTOS (Taipei, 6-11 March 2023), CIMT (Beijing, 10-15 April 2023), FABTECH (Monterrey, 16-18 May 2023), FITMA (Mexico City, 20-22 June 2023), FABTECH (Chicago, 11-14 September 2023), EMO Hannover (18-23 September 2023), CIBUS TEC (Parma Fairs, 24-27 October 2023), FORMNEXT (Frankfurt, 7-10 November 2023), IMTEX FORMING 2024 & TOOLTECH (Bangalore, 19-23 January 2024), SAMUEXPO (Pordenone, 1-3 February 2024), CCMT (Shanghai, 8-12 April 2024).

Events

Hotel Canada Urban Chic

Hotel Canada Urban Chic (Milano center)

Special offer – 34.BI-MU. 20% discount on the best online price

Located in Milan’s beating heart, 900m from Piazza del Duomo, 300m from Missori station and 15 minutes from the Central Station.

Located in Milan’s beating heart, 900m from Piazza del Duomo, 300m from Missori station and 15 minutes from the Central Station.

Superior, Executive rooms and panoramic rooms, all designed with a modern/minimal style, equipped with LCD TVs, SKY channels, minibar and free WiFi available in all areas of the hotel.

Continental buffet breakfast, always offered, with freshly baked cakes and pastries by our chef, as well as an assortment of locally grown fruit and vegetables.

Young, dynamic and multilingual staff, available 24/7 to assit you during your stay.

Paid parking available in the hotel’s immediate surrondings.

Lobby bar available around the clock for cafeteria, aperitifs and after dinner cocktails.

By booking directly on canadahotel.it and entering the code HC2024 you are entitled to a 20% discount on the best online price.

Hotel Canada Urban Chic

Via Santa Sofia 16

20122 Milano MI

Ph. +39 02 58 304 844

[email protected], [email protected]

www.canadahotel.it

![]()

Events

Hotel Canada Urban Chic

Hotel Canada Urban Chic (Milano centro)

Special offer – 34.BI-MU. 20% discount on the best online price

Located in Milan’s beating heart, 900m from Piazza del Duomo, 300m from Missori station and 15 minutes from the Central Station.

Located in Milan’s beating heart, 900m from Piazza del Duomo, 300m from Missori station and 15 minutes from the Central Station.

Superior, Executive rooms and panoramic rooms, all designed with a modern/minimal style, equipped with LCD TVs, SKY channels, minibar and free WiFi available in all areas of the hotel.

Continental buffet breakfast, always offered, with freshly baked cakes and pastries by our chef, as well as an assortment of locally grown fruit and vegetables.

Young, dynamic and multilingual staff, available 24/7 to assit you during your stay.

Paid parking available in the hotel’s immediate surrondings.

Lobby bar available around the clock for cafeteria, aperitifs and after dinner cocktails.

By booking directly on canadahotel.it and entering the code HC2024 you are entitled to a 20% discount on the best online price.

Hotel Canada Urban Chic

Via Santa Sofia 16

20122 Milano MI

Ph. +39 02 58 304 844

[email protected], [email protected]

www.canadahotel.it

![]()

Events

Mokinba Hotels

Mokinba Hotels: Montebianco, King e Baviera (Milan)

Special offer 34.BI-MU

Mokinba Hotels is an Italian hotel chain based and headquartered in Milan. The group was founded in November 1990, as a project aimed at establishing a Milanese hotel hub based on solid hospitality skills. The name combines the initial syllables of the first three hotels established: Montebianco, King and Baviera.

Mokinba Hotels is an Italian hotel chain based and headquartered in Milan. The group was founded in November 1990, as a project aimed at establishing a Milanese hotel hub based on solid hospitality skills. The name combines the initial syllables of the first three hotels established: Montebianco, King and Baviera.

Download the presentation of the Mokinba Hotels.

Hotel Montebianco is the flagship of the Mokinba Hotels group. Completely renovated is equipped with every comfort, meeting rooms, large private and guarded parking. This hotel is located near Fieramilanocity one of the most dynamic and growing areas of Milan. Just 20 meters from the Metro M1 Lotto Red Line and M5 Lotto Lilla Line that connect in just 5 minutes the exhibition center of Rho Fiera and the city center. At 200 meters, in P.le Lotto the Bus Terminal stop to and from Malpensa airport.

Hotel King, without excitation, the king of the Mokinba group. The historic center, five minutes from the Duomo filled offers its guests every comfort. It has been renovated over the years, while maintaining a style decor, offering guests an elegant welcoming environment with a comfortable and familiar atmosphere.

The Hotel Baviera has been completely renovated in the common areas. Its location is its strong point. Located just minutes from Milano Centrale Train Station and 50 meters from the metro “Repubblica” Yellow line. The bus terminal for Linate, Malpensa and Orio al Serio airports is 300 metres from the hotel.

Special offer 34.BI-MU

| MONTEBIANCO Mokinba Hotels |

KING Mokinba Hotels |

BAVIERA Mokinba Hotels |

|

|

|

| Via Monte Rosa 90 – 20149, Milan Phone +39 02 48012130 [email protected] |

Corso Magenta 19 – 20123, Milan Phone +39 02 874432 [email protected] |

Via P. Castaldi 7 – 20124, Milan Phone +39 02 6590551 [email protected] |

| Consult the special rates and fill in the booking form |

Consul the special rates and fill in the booking form |

Consult the special rates and fill in the booking form |

For more information on the MOKINBA agreement:

Phone +39 339 6953818, [email protected]

www.mokinba.it

![]()

Events

Mokinba Hotels

Mokinba Hotels: Montebianco, King e Baviera (Milan)

Special offer 34.BI-MU

Mokinba Hotels is an Italian hotel chain based and headquartered in Milan. The group was founded in November 1990, as a project aimed at establishing a Milanese hotel hub based on solid hospitality skills. The name combines the initial syllables of the first three hotels established: Montebianco, King and Baviera.

Mokinba Hotels is an Italian hotel chain based and headquartered in Milan. The group was founded in November 1990, as a project aimed at establishing a Milanese hotel hub based on solid hospitality skills. The name combines the initial syllables of the first three hotels established: Montebianco, King and Baviera.

Download the presentation of the Mokinba Hotels.

Hotel Montebianco is the flagship of the Mokinba Hotels group. Completely renovated is equipped with every comfort, meeting rooms, large private and guarded parking. This hotel is located near Fieramilanocity one of the most dynamic and growing areas of Milan. Just 20 meters from the Metro M1 Lotto Red Line and M5 Lotto Lilla Line that connect in just 5 minutes the exhibition center of Rho Fiera and the city center. At 200 meters, in P.le Lotto the Bus Terminal stop to and from Malpensa airport.

Hotel King, without excitation, the king of the Mokinba group. The historic center, five minutes from the Duomo filled offers its guests every comfort. It has been renovated over the years, while maintaining a style decor, offering guests an elegant welcoming environment with a comfortable and familiar atmosphere.

The Hotel Baviera has been completely renovated in the common areas. Its location is its strong point. Located just minutes from Milano Centrale Train Station and 50 meters from the metro “Repubblica” Yellow line. The bus terminal for Linate, Malpensa and Orio al Serio airports is 300 metres from the hotel.

Special offer 34.BI-MU

| MONTEBIANCO Mokinba Hotels |

KING Mokinba Hotels |

BAVIERA Mokinba Hotels |

|

|

|

| Via Monte Rosa 90 – 20149, Milan Phone +39 02 48012130 [email protected] |

Corso Magenta 19 – 20123, Milan Phone +39 02 874432 [email protected] |

Via P. Castaldi 7 – 20124, Milan Phone +39 02 6590551 [email protected] |

| Consult the special rates and fill in the booking form |

Consul the special rates and fill in the booking form |

Consult the special rates and fill in the booking form |

For more information on the MOKINBA agreement:

Phone +39 339 6953818, [email protected]

www.mokinba.it

![]()

Events

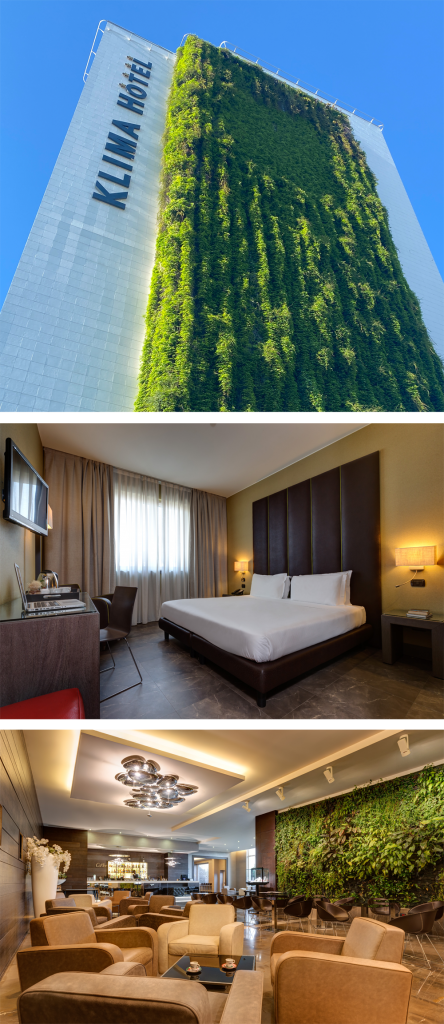

Klima Hotel

Klima Hotel (Milano)

Special offer – 34.BI-MU

Strategically located 5 minutes from the Fiera di Rho fair, situated in front of the new MIND pole (Milan Innovation District) and the brand new Galeazzi-Sant’Ambrogio hospital, our hotel has direct connections to the city centre thanks to its proximity to the red subway, Molino Dorino.

The hotel is very close to the highway for easy access to the international airports of Linate (LIN) and Malpensa (MXP). The hotel, classified as a 4-star superior, has 175 rooms, 6 meeting rooms, a free fully equipped gym, a small spa, a large outdoor car park, a garage and a restaurant where you will find delicious traditional Italian dishes.

• We are the first green and eco-sustainable hotel in Milan located 5 minutes from the Fiera di Rho fair and from the Merlata Bloom shopping center

• 175 rooms, 6 meeting rooms, a panoramic terrace located on the 14th floor, an outdoor parking, two underground garages, a gym, a spa and an indoor restaurant open for lunch and dinner.

• Reception 24/24

• Free use of our Technogym equipped gym

• Wi-Fi included in all rooms and common areas

• Online concierge to give you all the useful information during your stay

To make reservations for the period of the 34.BI-MU from 9 to 12 October 2024, please send an email to [email protected] in order to take advantage of an advantageous rate, mentioning that you have seen the hotel information sheet on the event website.

Klima Hotel Milano Fiere

Via Privata Venezia Giulia, 8,

20157 Milano MI

Tel. +39 02 455 0461

www.klimahotel.com

![]()

Events

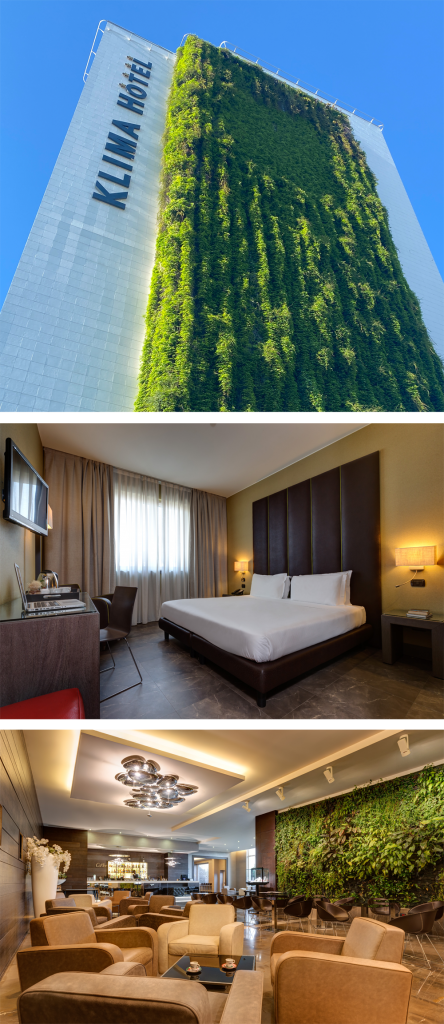

Klima Hotel

Klima Hotel (Milano)

Special offer – 34.BI-MU

Strategically located 5 minutes from the Fiera di Rho fair, situated in front of the new MIND pole (Milan Innovation District) and the brand new Galeazzi-Sant’Ambrogio hospital, our hotel has direct connections to the city centre thanks to its proximity to the red subway, Molino Dorino.

The hotel is very close to the highway for easy access to the international airports of Linate (LIN) and Malpensa (MXP). The hotel, classified as a 4-star superior, has 175 rooms, 6 meeting rooms, a free fully equipped gym, a small spa, a large outdoor car park, a garage and a restaurant where you will find delicious traditional Italian dishes.

• We are the first green and eco-sustainable hotel in Milan located 5 minutes from the Fiera di Rho fair and from the Merlata Bloom shopping center

• 175 rooms, 6 meeting rooms, a panoramic terrace located on the 14th floor, an outdoor parking, two underground garages, a gym, a spa and an indoor restaurant open for lunch and dinner.

• Reception 24/24

• Free use of our Technogym equipped gym

• Wi-Fi included in all rooms and common areas

• Online concierge to give you all the useful information during your stay

To make reservations for the period of the 34.BI-MU from 9 to 12 October 2024, please send an email to [email protected] in order to take advantage of an advantageous rate, mentioning that you have seen the hotel information sheet on the event website.

Klima Hotel Milano Fiere

Via Privata Venezia Giulia, 8,

20157 Milano MI

Tel. +39 02 455 0461

www.klimahotel.com

![]()

Events

Hotel Pierre

Hotel Pierre (Milano center)

Special offer 34.BI-MU

A vibrant mixture of history and current events, in the centre of Milan reflects the spirit of the city. In the heart of one of the most exclusive districts, with its majestic architecture of the Cathedral and the cultural tradition of the Theatre on the Staircase, the antique shops and sophisticated restaurants, the hotel’s location is of an unparalleled distinction.

A vibrant mixture of history and current events, in the centre of Milan reflects the spirit of the city. In the heart of one of the most exclusive districts, with its majestic architecture of the Cathedral and the cultural tradition of the Theatre on the Staircase, the antique shops and sophisticated restaurants, the hotel’s location is of an unparalleled distinction.

Luxurious and intimate, the Hotel Pierre Milan gives one an atmosphere of refined elegance the type appreciated by discerning travellers.

SERVICES

Connection to Wi-Fi in all rooms, complimentary

Direct Telephone

Satellite TV and Sky Full channel

Living area with sofa and desk (Suites)

Electronic safe

Individual temperature control

Check –in 14.00

Check-out 12.00

Hotel Pierre Milano

City Center – Free WI-FI

Via De Amicis, 32 – 20123 – Milano

Tel: +39.02.72000581 – [email protected]

10% discount if you book directly on www.hotelpierremilano.it and enter UCISIS code.

![]()

Events

Domina Milano Fiera Hotel & Congress

Domina Milano Fiera Hotel & Congress (Novate Milanese MI)

Special offer 34.BI-MU

Domina Milano Fiera Hotel & Congress 4 stars Business hotel is perfectly suitable to the needs of every exhibitor and visitor.

The 194 rooms are double-based starting from 20 square metres size, perfect for long and short stays, and lately renovated with an elegant and new wood flooring.

The Executive rooms comes with an exclusive set of amenities as bathrobe and slippers, free minibar, kettle and indoor parking.

Domina Milano Fiera is located 3 km far from fieramilano Rho fairgrounds and 700 metrs far from the Trenord train station that allows to get to the center of Milan in 15 minutes after a day of work at the fair.

A free shuttle is available on trade fair days to reach the fairgrounds without having to book parking.

parking

Meeting rooms are available for one-to-one meeting or for pre-exhibition briefing.

Services included in the booking:

– Shuttle A/R on exhibition dates

– Outdoor parking

– Fitness room

– Laundry service

– Unlimited wifi connection

– American Buffet breakfast

Domina Milano Fiera Hotel & Congress ****

Via Don Orione 18/20, 20026 Novate Milanese (MI)

Tel: +39 02 3567991

www.dominamilanofiera.com

![]()